Prototype

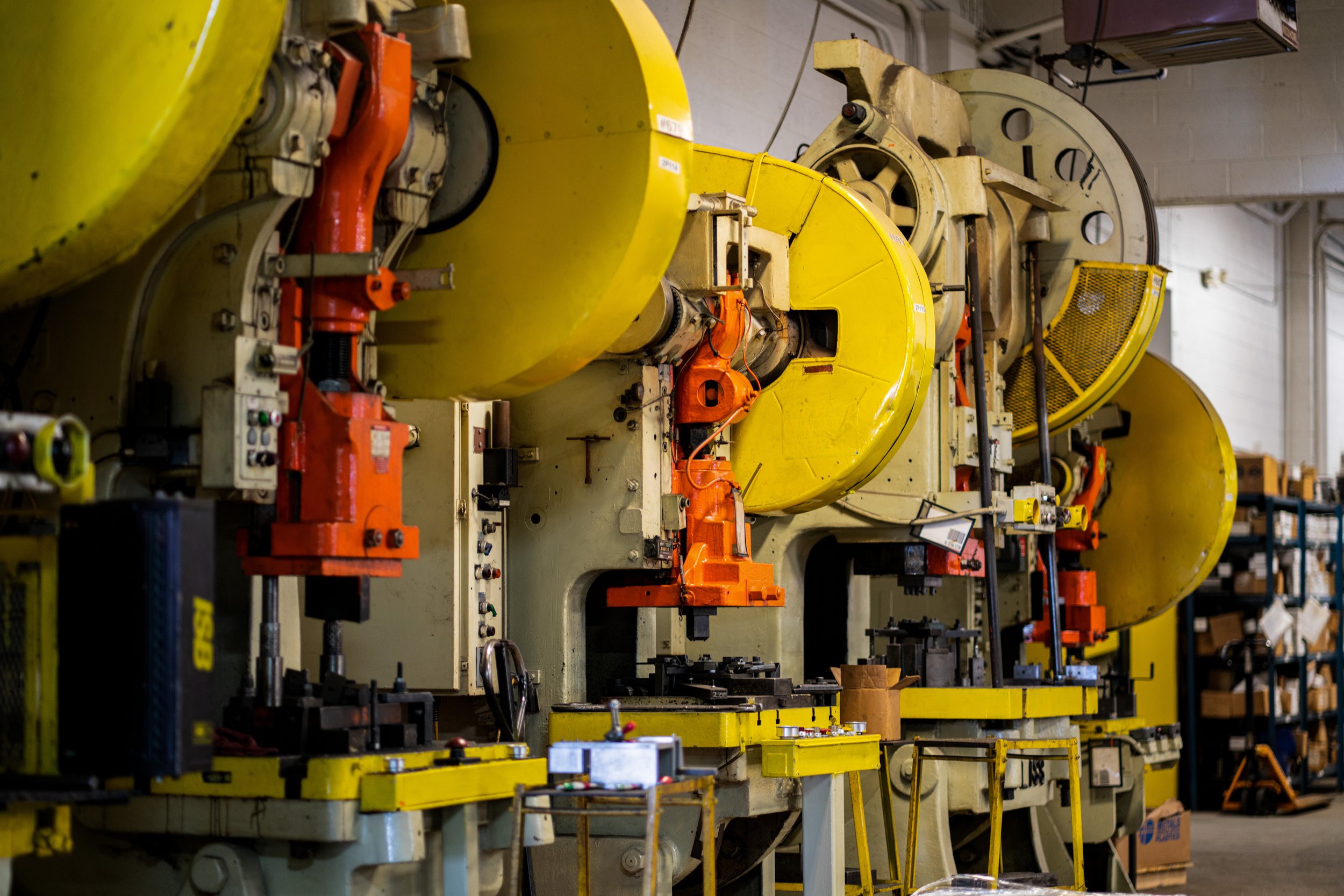

PTM can meet your emergency production demands so you avoid costly delays on your project. Our heritage of prototype processes is in small complex parts such as brackets, fasteners, and clips.

We soon graduated to much larger parts and today prototype parts ranging in size from a paper clip up to car hoods, side panels or mower deck lids. Large or small we've done it all! One-piece or several thousand, we are standing by to serve your prototype needs.

Rapid metal prototype processes are valuable production intense parts to:

Validate fit and function

Evaluate alternative designs

Solve manufacturing issues

Solve timing or launch issues

Our prototype processes are also a great short run or low volume production alternative when production required quantities are low.

Large Prototypes

Here at PTM, we utilize two distinct types of prototyping processes. During the initial design and analysis phase, we will determine which process best fits your project.

Part size and shape are generally the driving determinant for the type of process needed. Our large prototype process, sometimes referred to as "Crash Forming" is ideally suited for things like door panels, hoods, mower decks, oil pans, washer and dryer panels, or car fenders for example.

Advanced 3D simulation software, coupled with our varied and wide ranging experience instill confidence and trust. With turn times in as little as 4 weeks – CAD data to part – our rapid prototype department will turn you into the hero who saves the day! Our OEM customers trust and depend us for their large part prototype needs. Give us a try and you will not be disappointed either.

Small Prototypes

During the initial design and analysis phase, we will determine which process best fits your project.

Part size and shape are generally the driving determinant. Small clips, wire wraps, brackets, and fastener prototyping will generally follow these basic steps and fall into the small prototype category.

For larger parts such as automotive fenders, deck lids or appliance panels, our Large Prototype process is the place for you.