Production

The PTM has many production capabilities. For example, our production stamping areas are capable of running fourslide, line, compound, and progressive dies up to 144" and 2000 tons.

By allowing us to design, prototype, tool and produce your part, we know with 100% certainty that you are buying the most cost-efficient package available. Select one of the production areas below, for more details!

Our services.

Prototyping and Low Volume Production

PTM can meet your emergency production demands so you avoid costly delays on your project. Our heritage of prototype processes is in small complex parts such as brackets, fasteners, clips, and wire clamps.

We soon graduated to much larger parts and today prototype parts ranging in size from a paper clip up to car hoods, side panels or mower deck lids. Large or small we've done it all! One-piece or several thousand, we are standing by to serve your production needs.

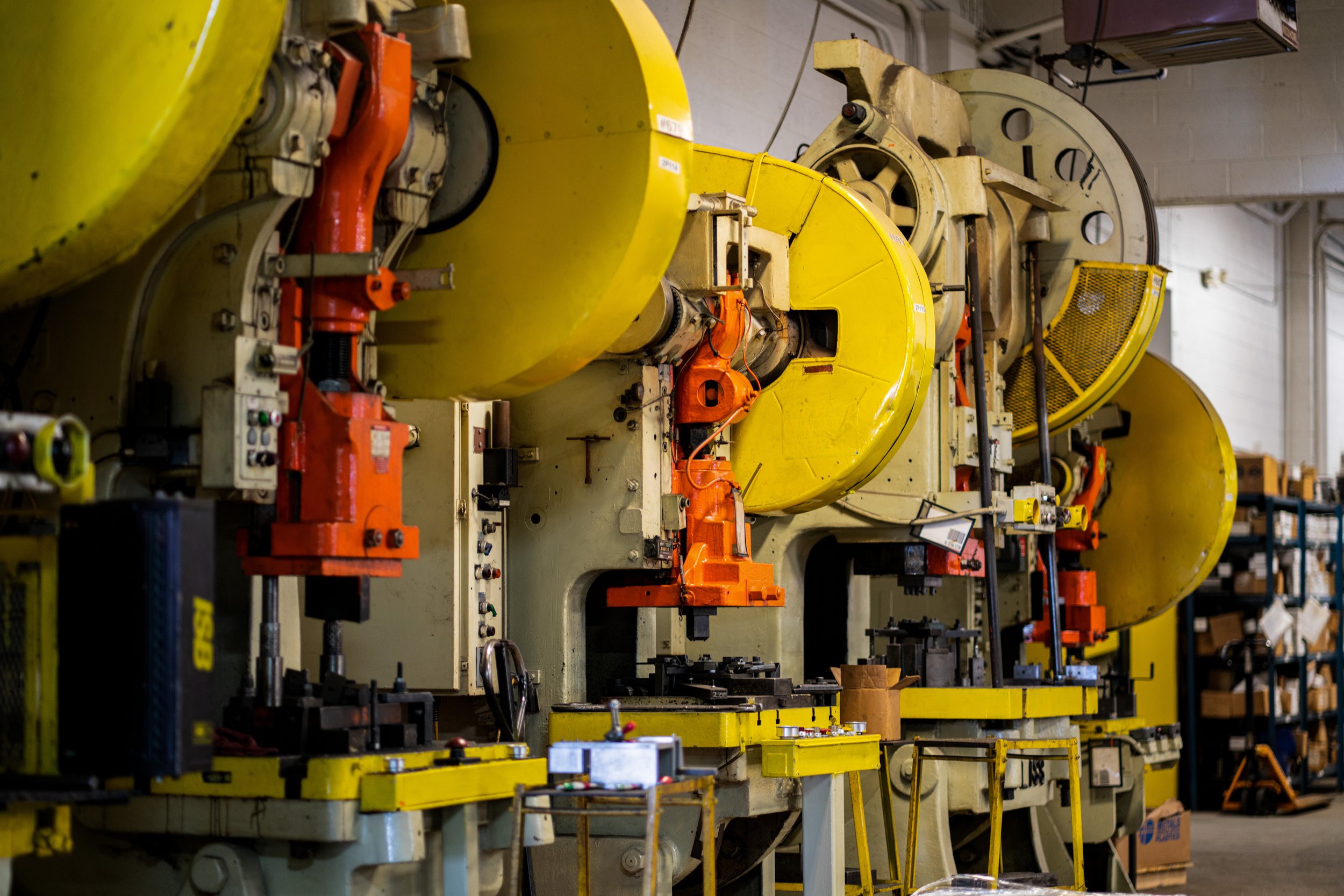

Production Stamping

PTM Corporation is a full service stamping facility capable of running progressive dies, fourslide and compound dies. From concept to production, our design team works closely with your engineers to develop the best part for fit and function. We find the most cost effective way to produce your part with minimal scrap and tooling cost.

We are capable of designing, building and running progressive dies any size up to 144" in length. Tonnage range from 60 to 600 for high volume production. Up to 2000 ton for low volume production (<5000 pieces).

Full Service Examples:

Wrap brackets

Air bag components

Complex, high precision fuel line connectors

Tight tolerance fasteners

Brackets

Roof Components

Conveyor Components

Clips

Terminals

Heat Shields

Bushings

Many others...

Laser Capabilities

PTM has a variety of laser cutting equipment to meet our customer's needs.

Equipment:

1 - Mazak Optiplex 3015 Fiber 3 – 8000 watt/Max Sheet Size 5’ x 10’

(1) New, Turbo X-48 Champion/1000 watt/Max.

Sheet Size: 4′ x 8′(1) Super Turbo X-48 Mark II/1500 watt/Max.

Sheet Size: 4′ x 8′(1) Super Turbo X-510 Mark II/2500 watt/Max.

Sheet Size: 5′ x 10′4 – 3 Axis Lasers

3 – 5 Axis Lasers

Materials We Cut:

Carbon – .010″ to 1″ thick

Alloy – .010″ to 1″ thick

Stainless – .010″ to 1″ thick

Aluminum – .010″ to 1″ thick

Copper – .010″ to .500″ thick

Brass – .010″ to .500″ thick

We stock many standard materials to meet our customer’s immediate delivery requirements.

Secondary Operations after Laser Cutting:

Stud and nut staking (robotic and manual)

MIG Welding

TIG Welding

Resistance Welding

Riveting

Tapping Holes

Component Assembly

Coining

All parts are cut to the customer’s print specifications or can be reverse-engineered from a customer supplied part.

Fourslide Manufacturing

PTM Corporation also offers fourslide manufacturing. Some benefits of utilizing this type of manufacturing process include:

Lower tooling cost

(up to 1/3 of traditional progressive die tooling)

Shorter lead time for tool build

Less material waste

Lower piece price due to less material waste

18 presses ranging from #1's to #4's

Check out videos of our machines in action and click here for more detailed information on fourslide machines!

Additionally, we offer compound die manufacturing. A compound die reduces design, build and tryout costs. Generally, compound dies are used for washer type parts, or parts simple enough to form in one hit or stroke of the press.